Description

FEATURES & BENEFITS

– Easy to clean – easy to remove and replace for cleaning – Sealed efficient, long life motors

– High performance – Flow up to 1100 US gals per hour – Easy to clean- snap fit assembly

– Efficient operation – Very low power consumption – Exclusive moisture tight seals

– Non-return valve included – to prevent backflow – Motor can be sold separately

– Marine grade silicon blocked, tin coated wiring – Stainless-steel motor shaft

– Five-blade impeller to ensure high flow rate – Anti-Airlock protection

– CE, RoHS, ISO 8846, ISO8849 standards – Quiet operation

– Submersible and ignition protected – 1 Year Warranty

– Low profile strainer – Leaves the bilge almost dry – New innovative split quick-connect joint design removes and installs in seconds!

– No need to disconnect base or plumbing when replacing pump, which can meet the needs of most users. |

DETAILS

|

1.High or low water sensing automatic mode, pump starts when water reaches 4.5cm/1.77” level, and stops when the current is less than 2.2A for 15 seconds. |

|

|

|

|

|

2.Low narrow design for tight/awkward bilge spaces for boats under 24m/79ft |

|

|

|

3. Low profile strainer – Leaves the bilge almost dry |

|

|

|

|

4. New innovative split quick-connect joint design removes and installs in seconds! No need to disconnect base or plumbing when replacing pump, which can meet the needs of most users. |

|

|

|

5. Include removable discharge straight and angel fittings to suit your installation. Threaded discharge nozzle. (3/4”+1”, 1’’+1-1/8’’ straight fittings and 1-1/8’’ elbow fitting). Multiple ports are available |

|

|

|

|

6. 1-1/8” 29mm 90o fitting sold separately with 360° rotation function to meet any angle installation requirement. No check valve with 90o fitting |

|

|

7. The pump body is designed with a 360-degree rotation function, which can quickly adjust any angle to meet installation requirements |

|

|

|

|

8. Motor can be sold separately |

|

|

|

9. Hidden Air Vents in the Body – helps prevent air locking in challenging plumbing installations and helps with the check valve |

|

|

|

|

|

10. Backflow Prevention – The non-return check valve prevents water left in the discharge from running back, keeping bilges dryer and cleaner |

|

|

STANDARD PUMP CONFIGURATIONS

| Model |

Flow rate |

Volts |

Current |

Head |

Mode of Operation |

Outlet Dia. |

N.W./G.W. |

| SFBP1-G800-14A |

800GPH |

12V |

3.2A |

3.2m/10.5′ |

water level sensor

automatic mode |

3/4″ (19mm)

1″ (25mm)

1-1/8″ (29mm) |

0.39/0.56kg |

| SFBP2-G800-14A |

800GPH |

24V |

2.0A |

3.2m/10.5′ |

0.39/0.56kg |

| SFBP1-G1100-14A |

1100GPH |

12V |

4.2A |

4.0m/13′ |

0.39/0.56kg |

| SFBP2-G1100-14A |

1100GPH |

24V |

3.0A |

4.0m/13′ |

0.39/0.56kg |

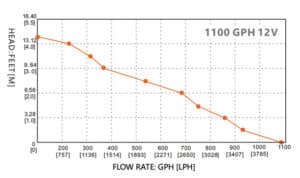

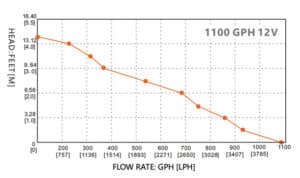

PERFORMANCE

DIMENSIONS

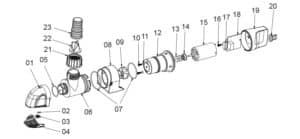

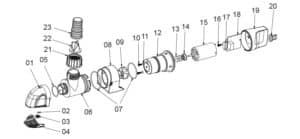

DETAILED COMPOSITION

| Key |

Description |

Quantity |

| 1 |

Filter Head |

1 |

| 2 |

Exhaust Bead |

1 |

| 3 |

Exhaust Valve |

1 |

| 4 |

Filter Net |

1 |

| 5 |

Inlet Seal Ring |

1 |

| 6 |

Pump Chamber |

1 |

| 7 |

Pump Chamber Seal |

2 |

| 8 |

Pump Base |

1 |

| 9 |

Impeller |

1 |

| 10 |

Machine Screw M3*8 |

2 |

| 11 |

Screw Seal |

2 |

| 12 |

Motor Cover |

1 |

|

|

| Key |

Description |

Quantity |

| 13 |

Oil Seal |

3 |

| 14 |

Oil Seal Seat |

1 |

| 15 |

Motor |

1 |

| 16 |

Self-tapping Screw |

1 |

| 17 |

Circuit Board Buckle |

1 |

| 18 |

Circuit Board |

1 |

| 19 |

Motor Back Cover |

1 |

| 20 |

Three-hole Line Card |

1 |

| 21 |

Lock Nut |

2 |

| 22 |

Check Valve |

1 |

| 23 |

25-29mm Straight Fitting |

1 |

|